SNV Uganda, Last Mile Intelligence Report

March, 2015

Background

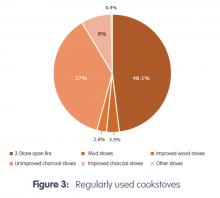

Uganda’s energy consumption matrix stands at about 90% biomass, 7% petroleum products and 2% of electricity produced from hydro and thermal power plants. Only 12% of the total population is estimated to have access to electricity of which only 1% comprises the rural population. People in Uganda depend almost exclusively on dim kerosene-fired lamps for light. Around 95% of the country’s population have to use the expensive and dangerous fuel because they do not have access to the electricity grid ad other modern energy alternatives. To exacerbate the worrying situation, the use of biomass hugely depends on traditional technologies such as three-stone fireplaces that have very low efficiencies (10%-17%). Consequently, communities are facing growing scarcity of access to firewood and charcoal with demand ever increasing while supply remains unsustainable

Government, NGOs, private sector and development partners have been implementing

a number of improved cookstoves (ICS) interventions however, access to ICS remains very low especially in rural [last mile] communities. Most funding for ICS has been through projects and programmes that in the end fail to attain sustainability beyond the implementation period. Consequently, adopters are frustrated after project periods with no access to repair, new ICS and other related services.

SNV in the Energy Sector

SNV has been working in Uganda’s energy sector providing technical support to the Uganda Domestic Biogas Programme. In 2014, SNV expanded its portfolio in renewable energy sector by adding support to scaling up market-based approaches to distribution of improved cookstoves and Pico solar photovoltaic (PV) systems. SNV is working with stakeholders

to develop long-term sustainable market based solutions that will encourage investments from public and private sector stakeholders while scaling up access to ICS and pico solar PV among last mile consumers.

Read the Study: http://stoves.bioenergylists.org/files/snv_market_intelligence_study_rep...