Estremera Nova, Bunyola, Illes Balears, Spain htttp://www.cuinessolars.jimdo.com

Marc Ayats Plana has been working on TLUD stoves and improved low thermal mass ovens. This TLUD powered low thermal mass oven was inspired by the Anderson's Recho Rocket Oven, and uses a Champion style TLUD heating stove to power the low thermal mass earth oven.

For Marc's excellent writ-up download the pdf TLUD-OVEN Description

These are some quick notes:

He has made some changes to the TLUD style oven

- Increased primary air draft, which can apport enough oxigen to burn the charcoal generated during the gasification process and continue giving heat to the oven. Now the primary air enters around the lower perimeter of the reactor, instead of having a single inlet tube like in the original model.

- Increased the length of the riser, which also sustains the diffuser. This extra extension allows the complete combustion of gases gasification to completely remove the visible smoke in the oven.

- TLUD Reactor. Diameter: 20cm. Total length: 30cm. Fuel Height: 20cm

- TLUD Outskirt. Diameter: 22cm. Diameter central hole: 10cm. Total length: 25cm

- TLUD Riser and diffuser. Diameter: 12 cm. Total length: 30cm. Diffuser: granite piece 2cm thick and 15cm diameter

- Fuel load: 3.38Kg pellets

The Low Thermal Mass oven is based on the Haiti Rocket oven http://www.rechoroket.com

To see more pictures of the TLUD oven and the process of construction go to:

http://cuinessolars.jimdo.com/forns/

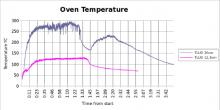

In the Oven Temperature graph, you can see the complete temperature profile. Marc did a side by side comparison of both a 20cm reactor TLUD and a smaller TLUD, with 12,5cm reactor.

"Note: the temperatures refers to the inside side of the wall oven, half way between the baking surface and the top hole. Note2: the temperatures were taken by a temperature datalogger and a type K probe."

Marc's Notes and TLUD size comparison are copied here:

Notes about 20cm TLUD test